The modern human habitat exists somewhere in between nature and artifice. For those of us who live in dense urban centers, we actually spend most of our time surrounded by artificial environments, made by man. Everything from the indoor spaces we rest and work in, to the schools where our children learn, to the malls and town streets we frequent, together make up the complex of this manufactured environment.

The true scale of this man-made environment on Earth is actually quite stunning. Many might be surprised to learn that the built environment is the single greatest consumer of energy in the world. Buildings, globally, consume one-third of all energy in the world. The built environment is an artificial, indoor habitat for humans. Just as the sun is required to sustain natural habitats like forests and fields, air conditioning, furnaces, light, and electricity are needed to sustain our indoor habitats.

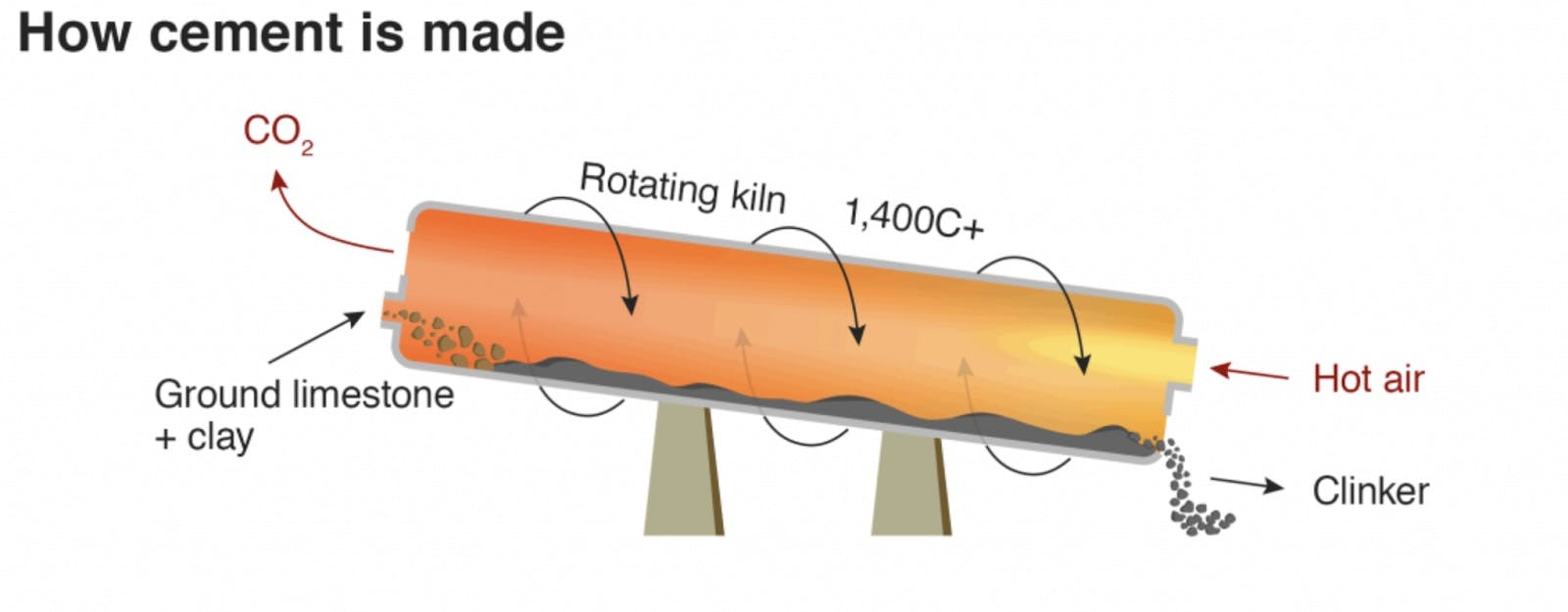

Beyond its high energy consumption, the built environment is also the greatest consumer of raw materials. Of all the raw materials consumed by humanity, 20-50% are used by the construction industry. Over the last century, the total amount of raw materials we consume annually has grown over 10x to more than 100 billion tons of material per year.

Source: Construction Materials

Over that span of time, the kinds of raw materials used also changed. As populations and demand for new construction grew, the characteristics we demanded of our building materials changed. Rather than merely needing to be strong and durable, like marble, they also needed to be abundant, like sand.

In due time, the whole world converged on a small set of materials that, today, make up the vast majority of everything built around the globe (i.e. concrete and steel). The future of our built environment – everything from its aesthetics, geometries, and the experiences it induces for the people who will need to live and work in these creations – will depend in large part on the materials that make it up.

Concrete: The Material That Built the Modern World

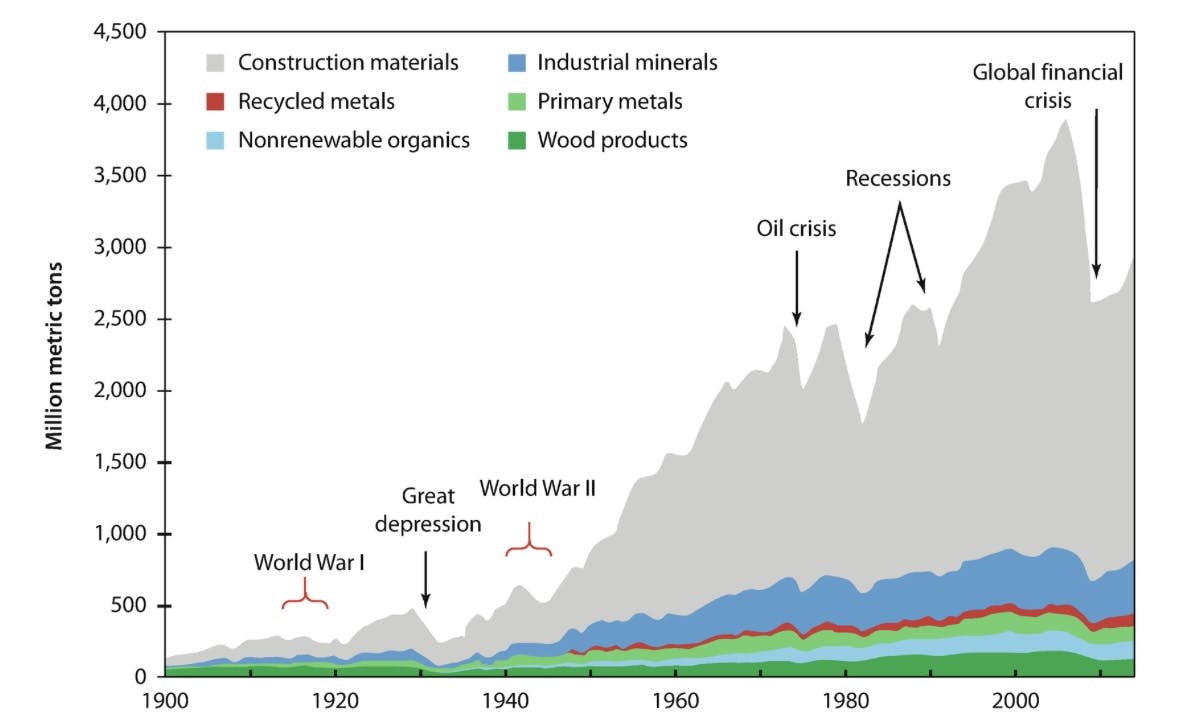

More so than any other, the material that makes up the built environment today is concrete. An interesting study conducted by the Weizmann Institute of Science in 2020 made the stunning point that by the year of the study’s publication, the weight of all inanimate human-made objects would exceed the total weight of Earth’s biomass. Furthermore, concrete — which accounts for half of all human-made things by weight, would exceed the weight of all biomass sometime around 2040.

Source: Nature

The concretization of the world shows no sign of abating as construction fervor all over the world is only heating up as populations grow and as developing nations industrialize and more of their residents move into cities. By 2060, an additional 2.6 trillion square feet of new floor area is expected to be added to the global building stock. This will be the equivalent of adding another New York City to the world each month for the next 40 years.

Construction at this scale requires a material that is as abundant as it is versatile. A material that can be extracted and transported as easily as it can be processed to produce strong structures. For more than a century, concrete has been that material of choice because its constituent ingredients are abundant, and because it can easily be cast to take on nearly any shape and produce a rigid structure with minimal effort relative to alternatives.

Concrete is made by combining just a few ingredients in a simple recipe. For every ten parts sand or gravel — also known as aggregates — it calls for one part water and two parts cement. Of these, cement is the only ingredient that requires some preparation ahead of time. It’s the key to making concrete stick together, as anyone who ever experimented with drying mud in the sun would know well. Dirt and water just crumble away when dry — it’s cement that makes all the difference.

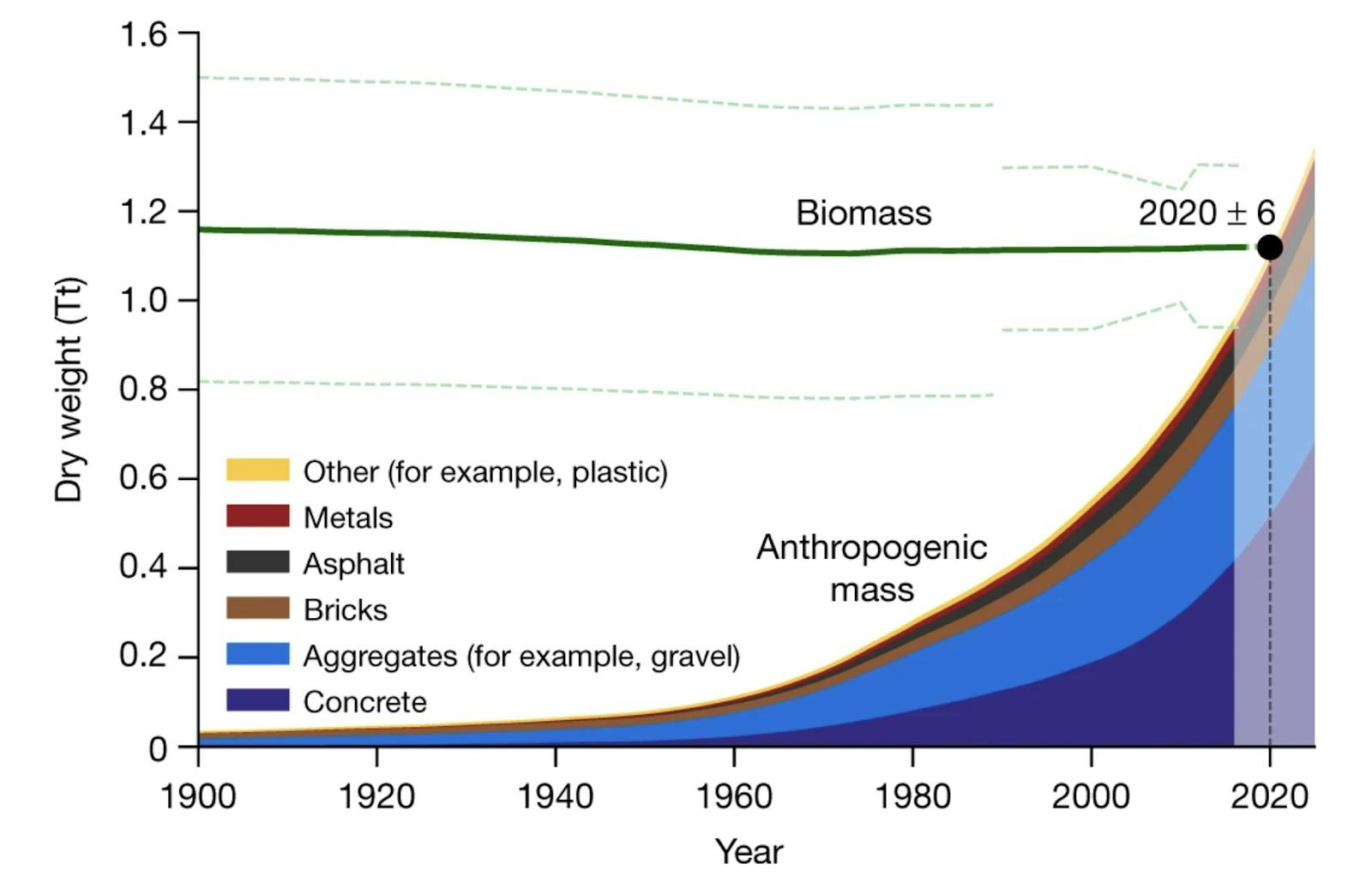

Cement is made of crushed limestone (CaCO3) and clay (SiO2). The limestone and clay are then fired up at temperatures reaching 1450 degrees Celsius, at which point carbon dioxide exits the mixture. Meanwhile, the left-over calcium, silicon, and oxygen react to form various calcium silicates. The resulting compound is known as ‘clinker,’ which is cement in condensed clump form. The clinker is then ground down into a fine powder to make true cement.

Source: Sustainalytics

Cement’s binding ability ultimately comes from the chemical reaction that takes place when it’s exposed to water. While you might think that the process of drying cement, water, and gravel together makes concrete, it’s actually the opposite. Instead, cement hardens through a process called ‘hydration’ where water is a critical component. Drying is actually harmful to the setting of concrete which is why everything possible is done to ensure that the concrete mixture is sufficiently hydrated during the hardening process.

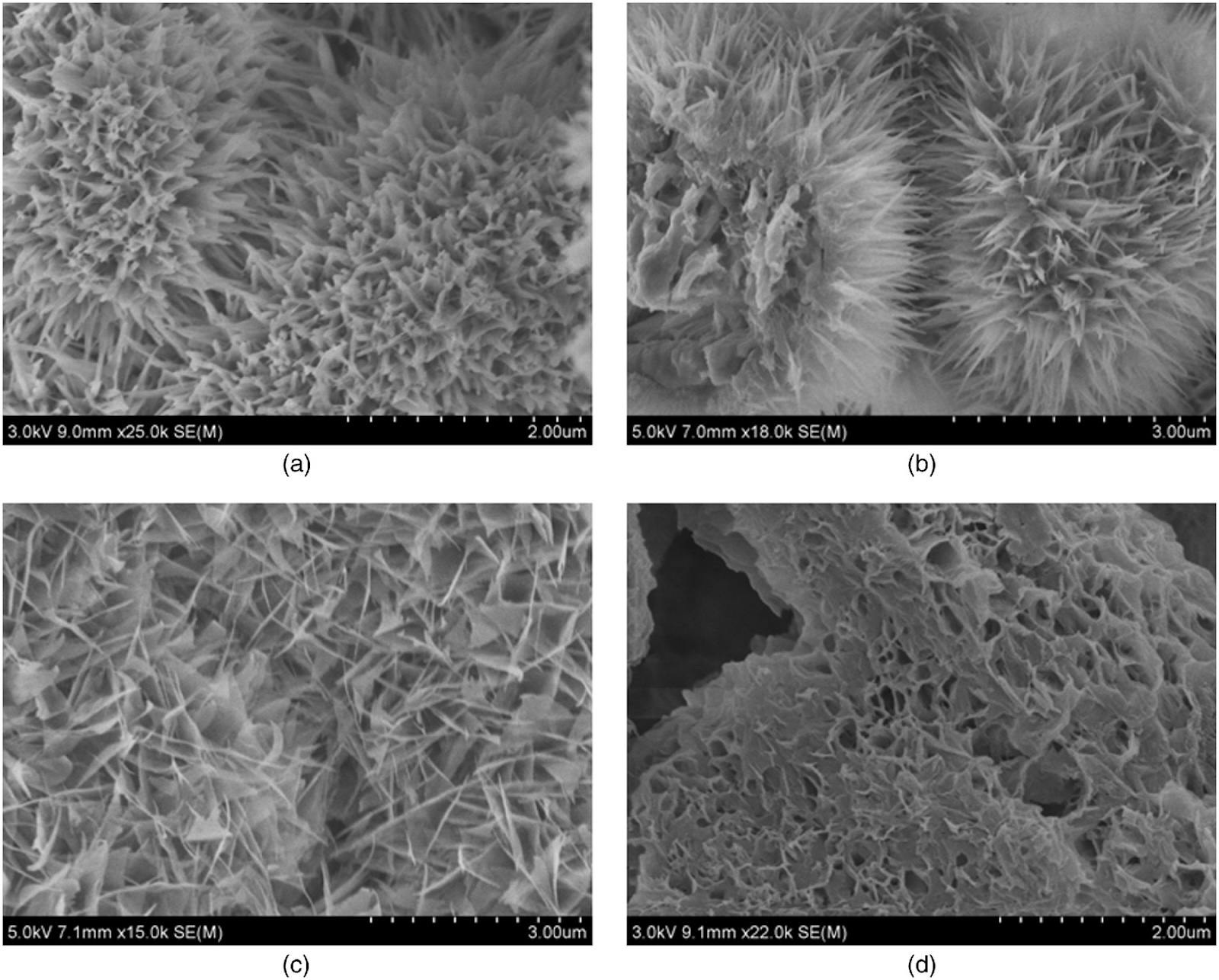

When exposed to water, the calcium and silicon ions inside the cement mixture are released into the water and start forming crystalline structures called ‘calcium silicate hydrates’. This reaction is actually exothermic, meaning it releases heat as it’s happening, so the concrete mixture heats up during the hydration process. The hydrates produce a gradually hardening substance, kind of like a gel, which binds the gravel, sand, and cement into one solid material: concrete.

Source: Calcium Silicate Hydrate Crystals Alex, Ilango, Ghosh 2022

The full hardening process takes a number of days to complete. Usually, within two weeks, the concrete mixture will have achieved 90% of its full strength. However, it will take an additional two weeks to achieve the remaining 10%.

On an annual basis, the world produces about 4 billion tons of cement alongside 42 billion tons of aggregates, both constituents of concrete. You can see how this material easily eclipses alternatives in terms of abundance — for example, only 1.9 billion tons of steel is produced each year. The largest producer of cement in the world is currently China, which in the two years between 2020 and 2021 produced more cement (4.9 billion tons) than the United States did during the entire 20th century (4.2 billion tons).

So it’s evident why concrete is such a miraculous material — it’s a recipe for cheap liquefied rock which hardens to produce a structure as strong as granite or marble. However, there are drawbacks to using concrete. One increasingly important issue with concrete production is that it is a rather dirty process. This is because the massive combustion of fuels required to heat cement kilns up to 1450 degrees Celsius, and the subsequent release of carbon dioxide from the limestone together account for 8% of annual greenhouse gas emissions.

Concrete’s drawbacks are not limited to just environmental concerns. Concrete’s brutal outward appearance, alongside its ubiquitous use around the world, has made modern cities feel cold and homogenous. Increasingly, these concerns beg the question of whether we will ever find an adequate alternative to the regime of concrete.

A History of Construction Materials

Despite the limited range of modern construction materials today, humanity used to build structures out of a number of diverse materials in the past. The earliest evidence of man-made habitats was found in the Olduvai Gorge in Tanzania in the form of building remnants dated to roughly 1.8 million BC. At this excavation site, there is evidence that circles of stones were stacked to prop up the wooden sides of a hut.

Other pre-historic building techniques involved constructing dolmens, where two stones are placed vertically with one mounted horizontally atop them. Dolmens like these can be found across the globe from Ireland to India and even Korea, where they were likely constructed some 4,000 to 5,000 years ago.

Source: Curious Ireland

Tents, anchored by wooden poles or animal bones with hides draped around, were also common around this time. More permanent structures followed the “wattle and daub” method. This involved creating walls out of small saplings or reeds, which were woven together with vegetable fiber before being plastered with wet clay to retain their structure.

The first recognizable human civilizations were marked by notable technological improvements in building methods, required to accommodate the growing populations they sought to house on the shores of river banks. These are the earliest examples we have of mass-managed and organized human construction.

In Mesopotamia, one of the most commonly used construction materials was brick. Bricks were made from mud and straw, both of which were ubiquitous in the river flood plains. These materials were mixed together and deposited into wooden frames to dry in the sun. Mud and straw bricks operate on the exact same principles as wattle and daub, as both use vegetable fibers and clay to create a durable material. The brick structure, however, ingeniously modularized this process allowing it to be re-oriented toward scale and repeatability.

Source: The National News

The Ancient Egyptians and Greeks, for their part, preferred stone as their material of choice for the monumental buildings that adorned their cities. Both civilizations developed impressive processes and techniques to lift massive pieces of rock dozens to hundreds of meters high. The Greeks, who built incredible marble constructions, never used any binding agents like mortar to hold their stone buildings together, opting instead for metal dowels or clamps. Ancient Greek constructions have now lasted millennia.

Source: Temple of Hephaestus in Athens, 449 BC Greeka

By far the most impressive builders of the ancient era, however, were the Romans. They were in fact the first to discover and widely use concrete in their constructions. Though it’s not clear exactly how they discovered concrete as such, architects like Vitruvius recorded in painstaking detail the components that went into producing it. A mixture of water, lime, volcanic ash, and rock was all it took to produce structures as strong and durable as the Colosseum, which has stood for nearly 2,000 years. Similarly, the Pantheon, with its 6-meter thick concrete walls, and its large concrete dome, 1.5 meters thick, suspended 43 meters above the ground, was built between 27-25 BC.

When the Roman Empire disappeared, so too did the knowledge of how to produce their particular form of durable concrete. Many claimed that Roman concrete had self-healing properties, meaning cracks that emerged would, over time, be patched by the material itself.

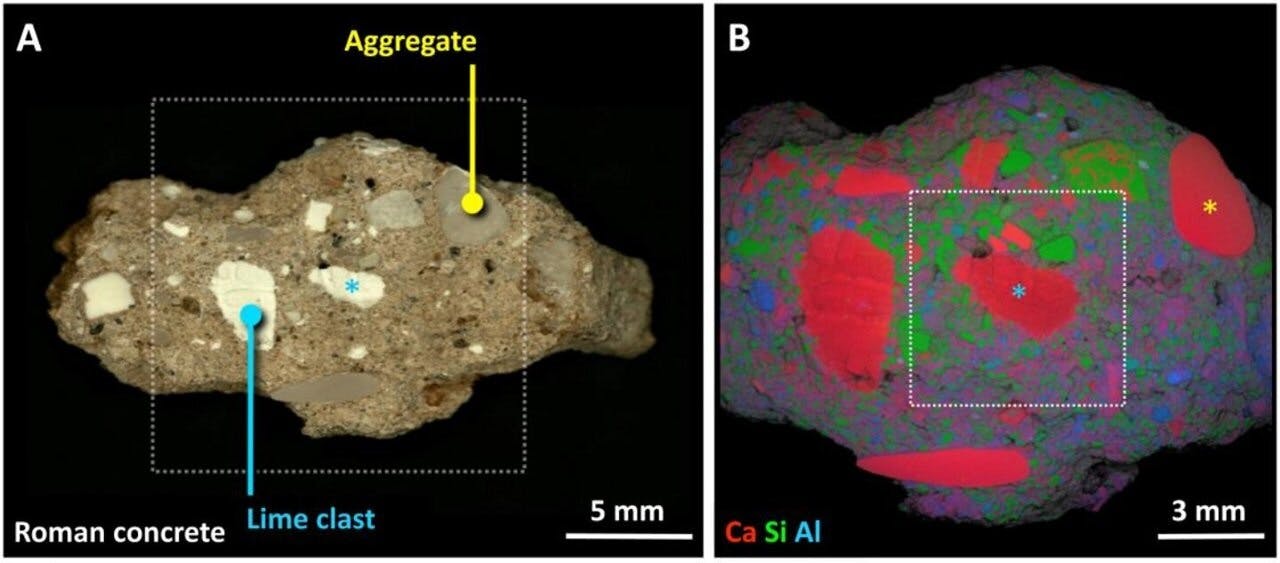

For a long time, the mystery of how to create Roman-style concrete was unsolved; however, in 2023, researchers at the Massachusetts Institute of Technology seem to have successfully deduced the secret of its creation. Upon observation, Roman concrete contains distinctive white minerals which are absent in modern concrete. For a long time, these features were considered imperfections in the Roman concrete mixture, however, the MIT team focused their attention on precisely how these spots came to be.

Source: Science

They soon realized that these white minerals, called lime clasts, were likely created during a process called 'hot mixing’, where the reactive quicklime was mixed together with water and volcanic ash all at the same time. The quicklime would react with water and induce an exothermic reaction raising the temperature of the mixture. The raised temperature would increase the rate of reactions occurring inside the concrete mixture, and ultimately decrease the time it took for the concrete to harden. The lime clasts, or pockets of reactive calcium, that were left over from this process, it turns out, were essential to the purported self-healing quality of Roman concrete.

As soon as tiny cracks propagated in the concrete, they would tend to travel through the high-surface-area lime clasts. Then, as water naturally seeped into these cracks, it would react with the calcium deposits and recrystallize as calcium carbonate within the cracks — healing itself.

Though we’re lucky to have just recently rediscovered this Roman technology, many construction techniques essentially had to be discovered anew following the disappearance of Roman know-how. Before concrete was re-discovered in the 18th century, Europe’s buildings depended largely on bricks. As the iron industry grew during the Industrial Revolution, builders switched to using iron for structural support with bricks being used as infill.

Finally, in 1756, John Smeaton, a British engineer considered to be the “father of civil engineering,” discovered the concept of hydraulic lime — or the phenomenon that limestone and clay, when mixed together, harden in the presence of water. It was a breakthrough new material until the more durable, faster-setting variety of Portland cement took its place nearly 70 years later, in 1824.

Portland cement was invented by an English bricklayer named Joseph Aspdin, who named it after the color of stone quarried on the Isle of Portland off the coast of Britain. Aspdin’s Portland method, involving the pulverizing of limestone and clay and burning them down into clinker, is still the method used for cement production today.

The next great innovation in construction materials came with the introduction of reinforced concrete. This was invented in 1867 by Joseph Monier, who demonstrated how concrete could be strengthened when metals with high tensile strengths were added. The principle was similar to wattle and daub, with the metal acting as the interweaving vegetable fibers and the concrete acting as the clay. Monier showed off his invention at the Paris Exposition of 1867.

By the 20th century, architects realized that cities were bound to not only grow out, but also up. The high rise dominated the bulk of that century’s most ambitious construction efforts. The Ingalls building in Cincinnati, named after its main investor, Melville Ingalls, was the first high-rise constructed using reinforced concrete in 1903. Its construction was considered a watershed moment because it contributed to engineers’ growing comfort with using concrete construction in high-rise buildings in the United States which became increasingly common from that point on.

Source: Ingalls Building, Reddit

The introduction of rubber as a sealant, artificial climate controls, and other such

developments also made high-rise structures more efficient and practical. Remarkably, many of the construction practices pioneered and perfected during the early 20th century to build the iconic high rises that dominate American skylines still comprise the state-of-the-art construction techniques.

The Future of Construction Materials

The century-old reliance on concrete, the construction of vast concrete jungles, and the proliferation of brutalist or otherwise cold styles of architecture that dominated the era of reinforced concrete construction have collectively encountered a great deal of pushback in the early innings of the 21st century.

The French architect Le Corbusier, who pioneered the economical style of concrete apartment buildings across Europe, and whose influence is witnessed in the characterless khruschevkas of the Soviet Union, is frequently cursed by those who find his gray, geometric constructions to be an eye-sore.

Source: Le Corbusier, Brittanica

The re-orientation of all design language and construction techniques toward concrete as a material is not only lamented by the aesthetically inclined, but even by engineers themselves. James Gordon, considered to be the founder of material science, wrote in his book Structures: Or Why Things Don’t Fall Down, that:

“The use of metals, which are so conveniently tough and uniform, has taken some of the intuition and also some of the thinking out of engineering.” On the whole, the introduction of steam and machinery resulted in a dilution of skills, and it also limited the range of materials in general use in ‘advanced technology’ to a few standardized rigid substances such as steel and concrete.”

Materials like stone and marble used widely to build much of the United States on the East Coast in particular, have now virtually disappeared from both the national supply and architects’ repertoires. Demand for stone has fallen and quarries have shuttered. Meanwhile, engineers are reluctant to even consider using the material since producers don’t have standards by which they can guarantee the material’s strength. Architect Amin Taha was quoted as saying, “the possibility that [stone], like bricks, could support the entire structure let alone its own weight has not been taught because it was at first rejected, then forgotten.”

Still, there are some emerging attempts to re-introduce forgotten materials into modern construction. Norway’s Mjøsa Tower, constructed in 2019, is the largest skyrise built entirely out of timber. In a similar vein, in 2018, a Japanese forestry company unveiled a proposal to build a 350-meter tall tower in the heart of Tokyo entirely out of wood. If constructed, the tower, called W350, would be Japan’s tallest and would be completed by 2041.

Source: ArchDaily

Other more exotic quests for new materials have led some researchers to study how fungi can be grown to form modular panels, from which walls and other supporting structures could be built. Fungi, like mycelium, also have the convenient property of offsetting the carbon footprint, since they capture twice their weight in CO2. It’s an interesting area of exploration since typically, fungal growths are what architects seek to avoid in construction.

Source: Fast Company

Though thought-provoking, the problem with all of these materials is the length of time it takes to extract, transport, and work them. None of the alternatives mentioned even come close to being as abundant, inexpensive, and most importantly, durable as concrete is.

That’s not to say that modern concrete can’t be improved on. Simply comparing its performance to that of Roman concrete shows us that we still have a long way to go in perfecting this material. Most concretes produced today have a life expectancy somewhere around 50-100 years. After that point, the concrete begins to deteriorate and has to be closely monitored for cracks or demolished and reconstructed.

Failing to stay vigilant about aging concrete structures can lead to disaster. The United Kingdom, which built several public buildings including schools and hospitals in the 1950s using a cheaper form of concrete called “aerated concrete” — with a lifespan of 30-50 years — has been devastated as some of these buildings have begun to fail. For example, the nation was stunned when in 2018, a primary school in Kent suddenly collapsed — though luckily no children were inside.

As a result, significant attention is being directed to discovering clever ways to make existing concrete production even more resilient and durable. One exciting line of research involves creating a futuristic concrete composite by infusing concrete with graphene. Graphene is a relatively novel material, discovered by researchers at the University of Manchester in 2004, who received the 2010 Nobel Prize in Physics for their achievement. It’s a single layer of carbon atoms arranged in a hexagonal lattice, often called the thinnest material known to man, but despite its thin composition, graphene is incredibly strong — two hundred times stronger and 6 times lighter than steel.

By incorporating graphene into the concrete mixture, the resulting composite material gains extraordinary strength and durability. Graphene’s strength is meant to prevent cracks from propagating throughout the material to increase its tensile strength. Think of it as reinforced concrete — but with a nano-platelet mesh instead of rebar. Interestingly, graphene is also a conductive material, which means there could also be the possibility of implementing it as a “flexible skin” for architecture. This could allow the exterior skins of buildings to become interactive, and responsive to weather, or human interaction.

Another advanced idea involves creating a new kind of self-healing concrete, this time with the help of living material — namely, microorganisms such as bacteria and other healing agents which would be embedded within the concrete mixture.

The company Basilisk, based in the Netherlands, has developed a kind of concrete, such that when internal cracks form, bacteria can enter the cracks and produce calcium carbonate to restore them if in the presence of water. The company claims that extending the shelf-life of traditional concrete would minimize concrete’s impact on the environment, as less cement would need to be produced.

On the other hand, perhaps all that stands in the way of a viable improvement on concrete is merely the Masic MIT Lab successfully commercializing their discovery of Roman concrete’s self-healing properties. Until then, however, the environmental impact of cement production and concrete is still a sore spot.

Some, concerned by its appearance and the pollution it causes are calling for us to limit its use in modern structures — applying it only to critical structural features like a building’s foundation or its columns while decorating the facade of the building with more beautiful and natural materials like wood or fungal panels.

On the other hand, perhaps it’s not entirely the materials that are at fault. After all, the Romans built some of the most beautiful structures in human history using concrete. The question is, why can’t we?

Disclosure: Nothing presented within this article is intended to constitute legal, business, investment or tax advice, and under no circumstances should any information provided herein be used or considered as an offer to sell or a solicitation of an offer to buy an interest in any investment fund managed by Contrary LLC (“Contrary”) nor does such information constitute an offer to provide investment advisory services. Information provided reflects Contrary’s views as of a time, whereby such views are subject to change at any point and Contrary shall not be obligated to provide notice of any change. Companies mentioned in this article may be a representative sample of portfolio companies in which Contrary has invested in which the author believes such companies fit the objective criteria stated in commentary, which do not reflect all investments made by Contrary. No assumptions should be made that investments listed above were or will be profitable. Due to various risks and uncertainties, actual events, results or the actual experience may differ materially from those reflected or contemplated in these statements. Nothing contained in this article may be relied upon as a guarantee or assurance as to the future success of any particular company. Past performance is not indicative of future results. A list of investments made by Contrary (excluding investments for which the issuer has not provided permission for Contrary to disclose publicly, Fund of Fund investments and investments in which total invested capital is no more than $50,000) is available at www.contrary.com/investments.

Certain information contained in here has been obtained from third-party sources, including from portfolio companies of funds managed by Contrary. While taken from sources believed to be reliable, Contrary has not independently verified such information and makes no representations about the enduring accuracy of the information or its appropriateness for a given situation. Charts and graphs provided within are for informational purposes solely and should not be relied upon when making any investment decision. Please see www.contrary.com/legal for additional important information.